In the demanding world of industrial materials, certain alloys stand out for their exceptional ability to withstand harsh environments. One such superstar is Alloy 904L. But what exactly is this material, often referred to as a "super austenitic stainless steel," and why is it chosen for critical applications where cheaper stainless steels like 304 or 316 fail? Simply put, Alloy 904L is a high-performance austenitic stainless steel specifically engineered to offer outstanding resistance to corrosion in a wide range of aggressive acidic and chloride-containing environments. Its unique chemical recipe makes it a go-to choice for industries where reliability and longevity are non-negotiable.

Alloy 904L Chemical Composition

The exceptional properties of Alloy 904L stem directly from its sophisticated chemical composition. Designated as UNS N08904, its core elements provide a powerful combination of corrosion resistance and material strength. Crucially, it features a high nickel content (23-28%) combined with significant chromium (19-23%) and molybdenum (4-5%) – this trio forms the foundation for excellent resistance to general and localized corrosion like pitting and crevice attack. What truly sets 904L apart is the intentional addition of copper (1-2%). This copper enhances resistance to reducing acids, particularly sulfuric acid, making it much more resilient than standard stainless steels. Low carbon content helps prevent harmful carbide precipitation. While iron makes up the majority of the balance, the overall effect is a carefully calibrated "recipe" optimized for performance under chemical stress.

Properties and Characteristics of Alloy 904L

Beyond its impressive corrosion resistance, Alloy 904L possesses several other desirable characteristics essential for demanding engineering applications. It retains the formability and weldability typical of austenitic stainless steels, although its higher alloy content requires slightly more care during processing. The material offers good mechanical strength and toughness, even at moderately elevated temperatures. Its high nickel content provides excellent inherent resistance to stress corrosion cracking (SCC), a common failure mode for standard grades like 304 or 316 in warm chloride environments like seawater or chemical brines. Additionally, like other austenitics, 904L is non-magnetic in its solution-annealed condition. These combined properties – durability in acids and chlorides, inherent toughness, and fabricability – make it a versatile choice for challenging designs.

Alloy 904L Corrosion Resistance

The standout reason for choosing Alloy 904L is its unmatched corrosion resistance profile, especially in challenging industrial settings. It performs exceptionally well in sulfuric acid across a broad concentration range and at moderate temperatures, largely thanks to its copper content. It also shows strong resistance to phosphoric acid, acetic acid, and various organic acids. 904L offers significantly better resistance to chloride-induced pitting and crevice corrosion than Type 316L stainless steel due to its elevated molybdenum levels. This makes it suitable for brackish water, seawater-cooled equipment (within limits), and environments containing chemical chlorides. Furthermore, it resists general corrosion effectively in mildly reducing conditions and demonstrates good performance against stress corrosion cracking in chloride environments, outperforming standard austenitic grades decisively.

Alloy 904L Industrial Applications

Given its corrosion-fighting prowess, Alloy 904L finds critical roles in industries where exposure to tough acids and chlorides is constant. A major application area is chemical and petrochemical processing. Here it’s used for reactors, vessels, storage tanks, piping systems, and heat exchangers handling sulfuric, phosphoric, acetic, and other acids where less resistant materials would rapidly deteriorate. It’s also widely employed in oil and gas production, especially in offshore platforms and pipelines dealing with corrosive formation waters, CO2, chlorides, and mild H2S conditions. Pollution control systems, such as flue gas desulfurization (FGD) scrubbers, rely on 904L for its acid resistance. Additionally, you’ll find it in pharmaceutical and food processing equipment due to its biocompatibility and ease of cleaning, and sometimes in high-end marine components where chlorides are a constant factor.

Alloy 904L: Fabrication and Welding

Despite having a higher alloy content than common stainless steels, Alloy 904L remains readily fabricable using standard methods required for austenitics, though adjustments may be needed due to its greater strength and work hardening rate. Cutting, forming, machining, and bending are all possible with appropriate tools and techniques. Welding 904L successfully requires careful attention. Common methods like TIG, MIG, and shielded metal arc welding are used. It’s vital to use low heat input techniques and matching high-nickel filler metals (such as ER385 or ENiCrMo-2/3) to preserve corrosion resistance in the weld area. Proper cleaning before and after welding is essential to avoid contamination. Crucially, after fabrication involving annealing temperatures, solution annealing followed by rapid quenching is highly recommended to maximize corrosion resistance by dissolving any potentially harmful micro-constituents formed during hot work and ensuring a homogenous, fully austenitic structure.

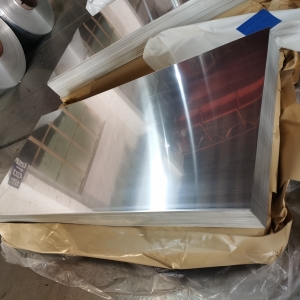

Choosing and Sourcing Genuine Alloy 904L

Given its use in critical applications, sourcing genuine Alloy 904L that meets stringent international specifications is paramount. Look for suppliers with proven expertise in high-performance alloys who provide material mill test reports (MTRs) verifying compliance with standards such as ASTM A240 (Plates/Sheets), ASTM A213 / A312 / B673 (Tubes/Pipes), ASTM A182 (Forgings/Fittings), ASTM B649 (Bar), EN 10088-2/3 or ISO 15510. These reports should meticulously confirm the chemical composition (specifically Ni, Cr, Mo, Cu content) and mechanical properties like tensile strength and yield strength. Reputable manufacturers maintain traceability from the melt origin through the entire production and testing process – from initial plate inspection and hydrostatic testing to full certification. Selecting an established supplier ensures you receive the correct alloy grade possessing the properties essential for your project’s demanding requirements, offering long-term reliability and value.

Conclusion

Alloy 904L stands apart as a premier super austenitic stainless steel renowned for its exceptional resistance to a potent cocktail of corrosive threats – particularly sulfuric, phosphoric, and acetic acids, as well as pitting and stress corrosion cracking caused by chlorides. Its performance stems from a unique chemical composition rich in nickel, chromium, molybdenum, and crucially, copper. This makes it the material of choice for critical components exposed to highly aggressive environments in the chemical processing, oil and gas, pollution control, and related industries. While fabrication, especially welding, demands expertise and proper heat treatment protocols following annealing temperatures, the investment is justified by the exceptional longevity and reliability Alloy 904L delivers where conventional stainless steels would fail, ensuring plant integrity and minimizing downtime. When specifying 904L, always insist on proper certification against recognized standards.