Market Overview

The polyimide films market is experiencing robust growth, propelled by heightened demand across numerous industry sectors such as electronics, automotive, and aerospace. Polyimide films, known for their remarkable durability, thermal stability, and resistance to harsh environments, play a vital role in applications that require materials capable of withstanding extreme conditions. Their unique properties such as high tensile strength, resistance to heat and chemicals, and lightweight structure make them ideal for a wide array of advanced industrial applications.

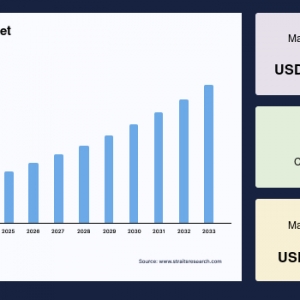

The global Polyimide Films Market Size was valued at USD 2.55 billion in 2024 and is projected to reach from USD 2.74 billion in 2025 to USD 4.92 billion by 2033, growing at a CAGR of 7.6% during the forecast period (2025-2033).

Key Properties and Manufacturing

Polyimide films are synthetic products made by polymerizing PMDA and ODA in potent solvents, resulting in robust, long-lasting materials. These films demonstrate exceptional temperature resistance, enduring environments ranging from 269°C up to 400°C. Due to these characteristics, polyimide films outperform conventional polymer films in applications demanding high heat stability. Their lightweight nature, alongside superior mechanical properties, enables their use in sectors where substituting heavier materials like metals and glass with durable films leads to improved efficiency and cost reduction.

The production process for polyimide films is technologically intensive, involving specialized film casting methods that require high temperatures and sophisticated equipment. This complexity contributes to higher processing costs but is offset by the superior performance and longevity offered by polyimide films.

Applications and End-Use Segments

Polyimide films are indispensable in a variety of applications:

-

Electronics: The electronics sector relies heavily on polyimide films due to increasing energy demand, technological advancements, and the proliferation of smart devices such as 3D TVs, smart TVs, tablets, and more. These films are often bonded with copper foil for printed circuit boards, and their favorable properties light weight, compactness, and durability make them suitable for portable computers, digital cameras, and advanced panel boards.

-

Automotive & Aerospace: The automotive industry benefits from the lightweight and strong characteristics of polyimide films, which are employed for wire insulation and as substitutes for heavier metals and glass. The aerospace sector values these films for their ability to withstand mechanical stress and extreme temperatures, essential for mission-critical applications.

-

Labeling & Packaging: Their thermal and chemical stability has expanded their role into packaging and labeling, where reliable multi-layer insulation is needed.

-

Other Sectors: Polyimide films are increasingly used as substrates in new-generation displays, lighting equipment, and flexible printed circuits, particularly where conventional polymers would fail due to heat limitations.

By application, the market is segmented into flexible printed circuits, specialty fabricated goods, capacitors, valve sheets, pressure-sensitive tapes, wire & cable, motor & generator, and more. Among these, the wire & cable segment is poised for rapid growth, especially in automotive and aerospace, where insulation requirements are stringent.

Regional Trends

The Asia-Pacific region currently dominates the global polyimide films market, driven by expanding automotive sectors and surging demand from electronic device manufacturers within the region. Innovations and product launches by key market players further contribute to the region’s leadership. Regional economic growth and increased industrial activities promote the adoption of polyimide films in a diverse range of applications.

Meanwhile, North America is forecasted to be the fastest-growing market. This surge is attributed to technological advancements, growing investment in research and development, and greater demand for modern electronic and automotive solutions.

Market Drivers

Several factors are fuelling market expansion:

-

Technological Innovation: The rise in innovation in consumer electronics, semiconductors, and wearables amplifies demand for polyimide films, particularly as manufacturers shift towards flexible, lightweight device formats.

-

Emergence of Smart Devices: Increased adoption of smart and connected devices requires films that can deliver performance in compact, heat-intensive environments.

-

Automotive Electrification: As the automotive industry evolves toward electric and hybrid vehicles, advanced materials like polyimide films are gaining favor for their electrical insulation and mechanical reliability.

-

Flexible Printed Circuits: The trend towards lighter, thinner, and flexible displays is driving adoption of polyimide substrate materials.

Challenges and Restraints

Despite the impressive outlook, the market does face challenges:

-

High Processing Costs: The cost-intensive nature of polyimide film production due to necessary high-temperature processes and specialized equipment acts as a barrier to broader adoption and investment.

-

Raw Material Instability: Fluctuations in raw material prices, limited supply chains, and high cost of chemical imidization reagents also curb market growth.

-

Material Limitations: While polyimide films excel in most areas, they demonstrate low resistance to hydrolysis and alkalis, limiting their suitability in certain environments.

Innovations and Future Prospects

Market innovation is especially evident in transparent polyimide films for the electronics and optoelectronics industries addressing the need for materials that combine flexibility with clarity and heat resistance. Major manufacturers are tailoring products to enhance properties and expand their usability for next-generation applications, such as foldable laptops and advanced display technologies.

Increasing investments in research, combined with ongoing advancements in manufacturing processes and material science, are expected to overcome existing limitations and unlock new opportunities for polyimide films in high-growth end-use sectors.

Conclusion

The polyimide films market is set for significant expansion over the coming years, fueled by its critical role in electronics, automotive, and aerospace industries. Despite high production costs and certain material limitations, continuous innovation, combined with increasing demand for advanced lightweight and durable materials, positions polyimide films as a cornerstone for future technological development across multiple sectors.