Introduction

The metalworking fluids market is undergoing significant transformation as global industrial activities expand and manufacturing becomes increasingly sophisticated. With rapid urbanization, a surge in the demand for automobiles, and the rise in infrastructure initiatives, the role of metalworking fluids (MWFs) has become more pronounced than ever. These fluids are essential to modern manufacturing, ensuring high-quality workpiece output, reduced tool wear, and optimized production processes. This article explores the major trends, growth drivers, segmental dynamics, regional insights, and the challenges shaping the future of the metalworking fluids market.

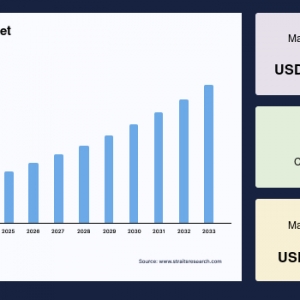

Market Overview

The global metalworking fluids market size was valued at USD 11.45 Billion in 2024 and is projected to reach from USD 11.91 Billion in 2025 to USD 16.3 Billion by 2033, growing at a CAGR of 4.1% during the forecast period (2025–2033).

Key Growth Drivers

-

Automotive Sector Expansion: The automotive industry's growth is a key catalyst for metalworking fluids, as these lubricants are vital in the fabrication, shaping, and finishing of metal automotive components. The rise in global vehicle production, driven by elevated consumer demand and growing disposable income, directly influences consumption patterns for metalworking fluids.

-

Manufacturing Complexity: The increasing sophistication of machinery and the need for precision engineering are also propelling demand. More complex production lines require advanced fluids to maintain tool longevity and ensure product quality.

-

Infrastructure Development: Governments and private sectors worldwide are investing heavily in transportation, connectivity, and industrial infrastructure. Each of these sectors relies on robust metalworking processes that necessitate efficient fluids for operations such as construction equipment manufacturing and metal component fabrication.

Segmental Analysis

Product Types

The metalworking fluids market is divided into mineral-based, synthetic, and bio-based fluid categories:

-

Mineral-based fluids: Widely used in grinding, turning, milling, and drilling operations, mineral-oil-based fluids are favored for their performance and cost-effectiveness.

-

Synthetic fluids: With increased focus on eco-friendliness, synthetic fluids are witnessing notable uptake, especially in industries seeking to reduce environmental impact.

-

Bio-based fluids: Despite environmental advantages, bio-based fluids face challenges due to relatively higher prices, restricting their widespread adoption in some markets.

Application Types

Applications for metalworking fluids are extensive, covering neat cutting oils, water cutting oils, soluble and semi-synthetic cutting oils, synthetic cutting oils, and corrosion preventive oils. Neat cutting oils hold the largest market share, owing to their prevalence in machine operations demanding high lubrication and heat dissipation. Water-based cutting oils, notable for their cooling properties, are also experiencing increased demand across multiple manufacturing processes.

End-Use Sectors

-

Machinery Manufacturing: The largest user segment, machinery manufacturing, benefits from high demand for heavy equipment and agricultural machinery, especially in emerging markets.

-

Other Industrial Segments: These include construction, electrical and power, agriculture, automotive, aerospace, rail, marine, telecommunication, and healthcare. Among these, the construction sector is experiencing the highest growth due to continuous infrastructure upgrades and urbanization trends.

Regional Insights

-

Asia-Pacific: This region is poised to register the fastest market growth. The presence of significant manufacturing capacity, vast infrastructure initiatives, and dynamic economic developments, particularly in China, India, and Japan, are key factors. Heavy investments in construction projects and export-oriented industrial activities further bolster demand.

-

North America: North America is anticipated to experience rapid uptake. Its leadership in technological innovation and the presence of highly developed economies stimulate growth in heavy machinery and high-value manufacturing, which are significant consumers of metalworking fluids.

-

Europe: A mature market with a strong tradition in automotive manufacturing and machinery exports. The region is characterized by its large-scale production of specialized machinery and high-end vehicles.

-

Latin America, Middle East, and Africa: These regions are contributing steadily to global growth, thanks in part to countries like Brazil, which is a notable exporter of construction vehicles and heavy equipment.

Challenges and Trends

While the metalworking fluids market is primed for growth, it faces several challenges:

-

Environmental and Health Concerns: Stringent regulations are being enforced due to the hazardous waste associated with disposal and health risks to workers exposed to certain chemicals. These concerns are catalyzing research and development into safer, more sustainable alternatives, such as synthetic and bio-based fluids.

-

Cost of Advanced Fluids: As industries move toward eco-friendlier solutions, higher costs remain a barrier to widespread adoption of bio-based options, especially in price-sensitive sectors.

At the same time, new trends are shaping the market's direction, such as the evolution of high-performance machinery and the need for advanced lubrication and cooling solutions for specialized manufacturing equipment. Innovation in fluid chemistry, aimed at balancing environmental safety, performance, and cost, will influence the competitive landscape moving forward.

Conclusion

The metalworking fluids market is at a pivotal point, responding dynamically to the demands of modern manufacturing, urban development, and eco-conscious production. With the expansion of end-use industries and the integration of technological advancements, the market is positioned for healthy growth. However, addressing environmental and cost challenges will be essential for sustained progress. Stakeholders that embrace innovation and sustainability will be best equipped to capture opportunities in the evolving metalworking fluids landscape.