Modern production environments rely on coordinated planning that blends architecture, engineering, and operational flow. As Yuanda Clean Room Solution continues drawing interest across healthcare manufacturing, electronics assembly, and research facilities, yd-purification introduces structured approaches that support organized construction and consistent performance. Could a unified system concept reshape how your facility operates each day?

Contemporary projects increasingly focus on holistic coordination rather than isolated components. Wall systems, ceiling grids, airflow paths, and service routes now evolve together, creating balanced interiors that support both people and processes. This integrated mindset allows technical teams to address layout challenges early, reducing later adjustments while improving overall spatial harmony.

Industry discussions frequently highlight the importance of adaptable layouts. Production demands change, equipment upgrades occur, and workflow patterns evolve. Modular construction techniques allow spaces to transform with minimal disruption, supporting continuous operation while maintaining interior stability. This flexibility has become a central expectation for modern clean facilities.

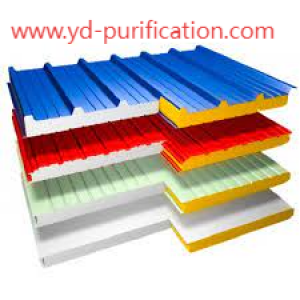

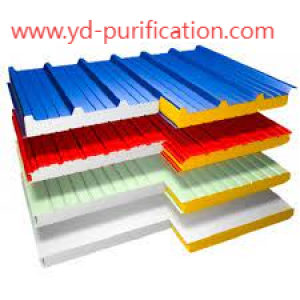

Material selection also influences long term performance. Smooth surfaces simplify daily care routines, while structured panels support stable airflow patterns. Thoughtful combinations of finishes and framing create environments that feel organized while supporting contamination control goals.

Energy coordination remains another priority. Electrical routing designed alongside mechanical systems helps distribute loads efficiently, supporting equipment reliability and simplified maintenance. Organized service access points allow technicians to perform inspections quietly, preserving daily productivity without unnecessary interruption.

Air management strategies shape occupant comfort and process accuracy. Balanced circulation supports pressure consistency across zones, helping maintain separation between controlled and transitional areas. This controlled movement of air contributes to operational confidence and supports sensitive activities.

Digital integration continues expanding across facility planning. Monitoring platforms connect temperature, humidity, and operational status into centralized dashboards, giving managers real time visibility. These tools help teams respond promptly to environmental changes while strengthening oversight across multiple rooms.

Construction sequencing plays a meaningful role in project outcomes. Coordinated installation schedules allow structural components and technical systems to progress together, reducing delays and supporting smoother handovers. This collaborative workflow encourages alignment between designers, installers, and end users.

Maintenance planning is now considered from the earliest design stages. Clearly defined access routes and organized equipment placement simplify routine servicing, extending system lifespan while supporting uninterrupted production cycles.

For organizations seeking structured environments that support evolving demands, yd-purification delivers coordinated planning frameworks shaped around real operational needs. Explore how Clean Room Solution concepts integrate into modern facilities by visiting https://www.yd-purification.com/ and consider whether your next project is ready for streamlined execution.