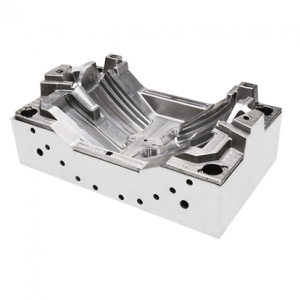

A toolbox mold is a specialized mold used in plastic injection molding to produce toolboxes of various sizes and styles. It defines the final shape, strength, and appearance of the product. These molds are commonly used to create durable plastic toolboxes for industrial, household, and automotive purposes. The mold’s precision determines how well the parts fit together—such as the lid, handle, and compartments—ensuring both functionality and an appealing design.

What Are the Main Structural Features?

The basic structure of a toolbox mold includes several key components: the mold base, core, cavity, and cooling system. The core and cavity form the outer and inner surfaces of the box, while the mold base supports the entire setup. Cooling channels are carefully designed to regulate temperature and maintain product consistency. Additionally, ejector pins are used to release the molded part once it cools. A well-constructed toolbox mold allows for smooth demolding and high repeat accuracy in every production cycle.

How Does Mold Design Affect Product Quality?

Design precision plays a vital role in determining the performance and durability of the final toolbox. Proper wall thickness, corner radii, and reinforcement structures ensure the box can handle heavy tools without cracking or deforming. High-quality molds also minimize surface defects such as sink marks or flashes. Manufacturers often use strong materials like hardened steel for molds to maintain stability during repeated production runs. This ensures that every toolbox meets consistent standards in strength and appearance.

Why Is the Toolbox Mold Essential in Manufacturing?

Toolbox molds contribute significantly to efficient mass production. They enable quick and consistent manufacturing, reducing both material waste and production time. Customizable mold designs also allow for product variations, such as different sizes, compartments, or locking systems. In short, toolbox molds combine precision engineering with practical design, making them a key element in creating reliable storage solutions for tools and equipment.

https://www.yiwei-mold.com/product/medical-mold/pacifier-molds.html

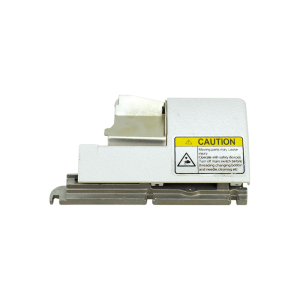

Pacifier molds are designed to produce the components of pacifiers, including the nipple, shield, and handle. The molds provide the precise shape and texture required for ideal performance, ensuring that the pacifiers are safe for infants to use. Additionally, pacifier molds may incorporate features such as ventilation holes, ergonomic designs, and orthodontic shapes to promote healthy oral development and comfort for babies.